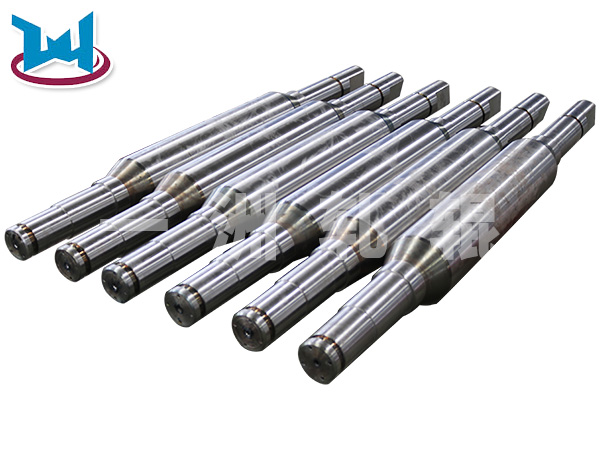

Forged steel work roll

Because forged steel work roll needs to change the shape of material at ordinary temperature, it is the most wearable spare part in strip rolling process. By using different materials such as 2% Cr, 3% Cr and 5% Cr, we can greatly improve the quality and service performance of rolls to meet the requirements of different customers.

Because forged steel work roll needs to change the shape of material at ordinary temperature, it is the most wearable spare part in strip rolling process. By using different materials such as 2% Cr, 3% Cr and 5% Cr, we can greatly improve the quality and service performance of rolls to meet the requirements of different customers.

Product Details| Product Name | Hardness range | Quenching depth | Hardness uniformity |

| Working Roll | 70-104HSD | 10-50mm | +/-1 HSD |

Roller produced by forging ingot. Forging can forge metallurgical defects such as looseness and shrinkage holes in ingot, and break up coarse casting structure to obtain high quality rolls with compact structure and uniform composition. Forged steel rolls have better strength and toughness, uniformity of surface hardness and fatigue resistance than similar cast rolls. (Table 1) In order to meet the specific requirements of different rolling mills and rolling conditions, different alloying elements can be added to roll steel to improve roll performance.

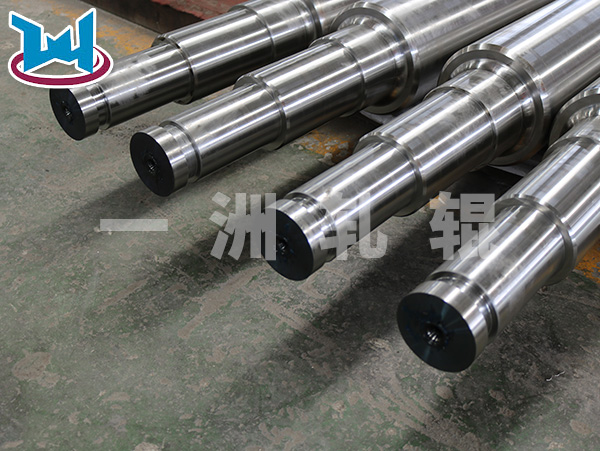

Forged steel roll

Roller produced by forging ingot. Forging can forge metallurgical defects such as looseness and shrinkage holes in ingot, and break up coarse casting structure to obtain high quality rolls with compact structure and uniform composition. Forged steel rolls have better strength and toughness, uniformity of surface hardness and fatigue resistance than similar cast rolls. (Table 1) In order to meet the specific requirements of different rolling mills and rolling conditions, different alloying elements can be added to roll steel to improve roll performance. Carbon and alloy elements have different effects on the structure and properties of forged steel rolls: carbon can increase hardness and strength of rolls, reduce plasticity and improve wear resistance; manganese can increase hardenability and strength; silicon can deoxidize and improve strength; chromium can increase hardenability and strength, improve wear resistance; molybdenum can increase hardenability. Vanadium can control the grain size of steel and increase its strength. The main chemical compositions of hot rolls and backup rolls of commonly used forged steel are shown in Table 2.

Focus on us

Focus on us