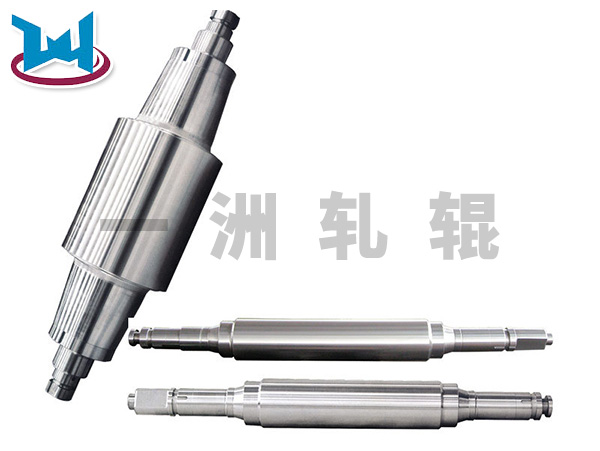

Forged steel intermediate roll

The intermediate roll is the core part of the rolling mill. The product is called 1400mm 12-high mill.

Intermediate roll specification: 225X1400X2592;

Technical parameters: roll body HSD80-85, hardness uniformity less than 3HSD, depth more than 25-30mm;

Roll diameter HSD55-60;

Material: MC3.

The intermediate roll is the core part of the rolling mill. The product is called 1400mm 12-high mill.

Intermediate roll specification: 225X1400X2592;

Technical parameters: roll body HSD80-85, hardness uniformity less than 3HSD, depth more than 25-30mm;

Roll diameter HSD55-60;

Material: MC3.

| Product Name | Hardness range | Quenching depth | Hardness uniformity |

| Intermediate Roll | 70-85HSD | 10-50mm | +/-1 HSD |

Intermediate roll shift:

The purpose of the intermediate roll axle shift function is to control the position of the upper and lower intermediate rolls in each frame. The mechanical equipment of the intermediate roll shifting device is designed to move under load, so that it can be operated and moved during rolling. The shape of strip steel can be affected by manually adjusting the reference value of the middle roll position of the four racks by the operator of the main console.

Performance of positioning system:

In the on-line training material for acid rolling in rolling workshop, the intermediate roll shifting of the stand can be manually controlled by an elastic reset switch on each stand operating box.

Normally, the axle movement of the intermediate roll is always synchronized between the upper and lower rolls, but in some cases, each roll needs to be controlled separately. Therefore, there is a three-choice switch on the rack operating box. The operator can choose to move simultaneously, the upper and lower intermediate rolls can move separately.

The actual position of the intermediate roll will be displayed to the operator in the form of mm in each rack operating box. There is a light key on the operating box of each frame to activate the change position of the middle roll. For the change position of the middle roll, the upper middle roll must be in a narrow position and the lower middle roll must be in a wide position.

There is a light key on the operating box of each stand to make the middle roll return to the rolling position after the roll change. At this time, the position of the roll return of the stand must be compatible with the position set by the actual MSU preset reference value. If there is no activation of the MSU preset reference value after the roll change, the position of the middle roll will be 1000mm.( At the same time, the light key can be used to locate the position of the intermediate roll at any time in the position specified by the preset reference value of MSU. The light of the indicator indicates that the intermediate roll is in the rolling position, the flashing of the indicator indicates that the positioning process is under way, and the flashing of the indicator indicates that the positioning process is under way if the indicator keeps flashing continuously. At the same time, the detailed error information is displayed in the alarm list of the main console of the rolling mill.

In this case, the preset reference value between two rolls is still automatically executed. For this function, the master console is equipped with button-type light keys to select the automatic or manual reference value. The actual reference value position will be drawn. The position reference value of the intermediate roll can be manually increased or lowered by operating the handle.

Next:Forged steel intermediate roll

Focus on us

Focus on us